Once again it is that time of the year when garment printing goes into a state of mayhem. Everyone wants their prints done yesterday and realistic turnaround times go out the window. With so much going on it can be easy to lose focus on some basic requirements to make it through the holidays without a hiccup. In addition to preparing for the rush, your printer also needs to be prepared for the downtime thereafter.

Take some time to assess your current inventory of ink, pretreatments and printing supplies. Depending on what you have on hand is it enough cover a heavy ordering situation due to the holidays? This may seem like a very simple thing to think about but last minute ink orders are very common for us. It is also very common that things are just too late and a few orders get missed out on and who wants that scenario?

Take some time to assess your current inventory and stock up.

So as we move into December of 2017 there is no time better than now to confirm that you are ready for the final holiday rush. Delays in shipping due to weather and packed delivery trucks can pop up at any moment.

Make sure that you are well stocked up with the following items for that holiday rush:

• Light Pretreatment

• Dark Pretreatment

• Heat Press Sheets

• Cleaning Solution

• CMYK Ink

• White Ink

Besides being a great time of the year to be profitable many of us have a moment to spend some well-earned time with family and friends. It’s that time to wind down from the Christmas rush and bring in the New Year. This may even be the time that many people take a vacation and leave the hustle and bustle of printing behind for a few weeks. No matter what your plans are this is a great opportunity to give your printer a good clean and maintenance before you say your goodbyes.

No matter what you should give your printer a good once over general maintenance.

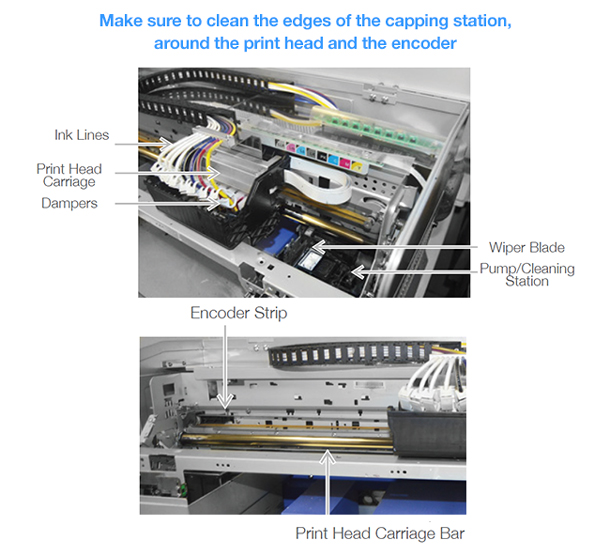

Make sure to clean the edges of the capping station, around the print head and don’t forget the encoder. Your printer should have come with a small container of grease in it to lubricate the carriage bar. Lubricate the carriage bar using a small amount of the Omni Grease.

Depending on how long it has been since you have last changed your dampers and wiper blade this may also be the golden opportunity to do so. We recommend that you do both of these around every 6 months. It is always better to change them out on a scheduled basis than waiting for them to go out on you. This way you can start off the New Year knowing your printer is ready to get to work on some serious orders. If you have never changed out dampers before you need to contact tech support and have them walk you through the process. You can always contact tech support via support@omniprintonline.com.

Here is a list of Consumable Parts you should always have on hand:

• Omni Grease for Carriage Bar

• Cleaning swab set

• Dampers (4-8)

• Super Cleaner

• Wiper blade

One of the great features of all FreeJet printers is the “Wet Capping” feature. Once the printer has been “Wet Capped” your print head will be protected for a good few weeks of downtime. If you are planning to not to use the printer for close to a month it is recommended to “Wet Cap” the printer using Super Nozzle Cleaner. If you need any help making sure your printer is going to be shut down safely for the holidays please contact tech support for help. In most cases, you will be shutting the printer down as you do on a daily basis. Everyone here at OmniPrint International would like to wish you a great holiday and a prosperous New Year.

For a detailed guide on recommended supplies to keep on hand download our PDF: FreeJet Main Components and Parts