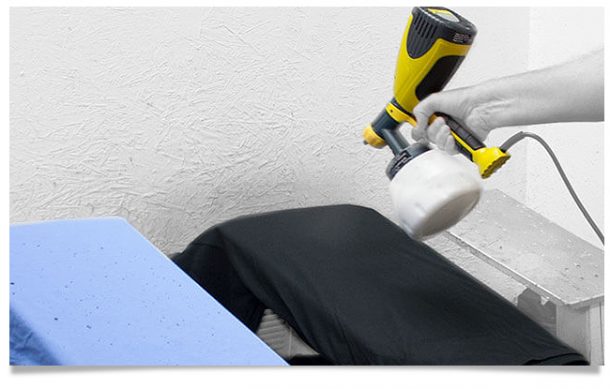

One of the largest learning curves when learning DTG is the pretreatment process for dark garments. Since day one the basic standard has been to apply the pretreatment using a Wagner Power Sprayer. This is a sprayer that would be used to paint your home or a garden fence.

Over the last few years the introduction of Pretreatment machines has become very popular and has many benefits. A major benefit is not having to go outside or set up a specific area to do it. Once the machines are dialed in they are also very consistent. They must be maintained and cleaned after use to keep them dependable.

The problem is when a pretreatment machine is purchased with a new printer. The hand pretreat process is not given as much or any attention. The machine is used and set up at a setting that may or may not be optimal. When learning by hand you will get an idea of the control and the amount needed for a good coating. Especially what the shirt should look like once pretreated to the right amount.

One more thing to keep in mind is that if your pretreatment machine goes down what do you do? If you do not maintain your machine it will malfunction very quickly. Pretreatment dries and has characteristics of white Elmer’s glue. You need to keep things clean and always flush out the nozzle and lines, just imagine dried white glue inside it. If it goes down and you don’t know how to hand spray a garment you will be stuck until the unit is working again.

This is not about what is better and both ways get the job done. The important thing is learning the process and understanding the amount and saturation needed. Doing so will help you move through your learning curve much faster. Just because you have the machine does not mean you are going to get perfect pretreat. This can cause a user to think everything is being done right but the prints are not good. So this must be the printer right? If you cannot look at a shirt and understand how well the machine has pretreated then a step back is needed. Take your time and learn by hand first. Once you are getting nice consistent prints then fire up the machine and dial it in. just keep it clean.